DIRAC

Software

A new, efficient way for test-based sound & vibration measuring

DIRAC completely changes the way you measure and model sound & vibrations. DIRAC allows engineers to measure FRFs with Virtual Point transformation, making reliable full-vehicle models available earlier in the development process.

DIRAC ensures traceability of results and indicates the quality of the measurement. Overall, DIRAC helps to avoid the final-phase troubleshooting – which can postpone vehicle production – and reduces the number of prototype variants needed. Limit the need to re-do measurements or to troubleshoot issues with emergency teams. In the early stages of vehicle R&D, full vehicle sound & vibration performance can already be estimated by combining measured and simulated FRFs. Over time these predictions can be updated to reflect changes in the design or decisions that have been made – thus saving valuable time and resources.

What to expect from DIRAC?

DIRAC is unique on many fronts, but truly outstanding are the intuitive way of guiding engineers during the measurement and the integration of the Virtual Point methodology. With the live quality indicators available in DIRAC, measurements will be done first-time-right. The measurement flexibility DIRAC offers has never been implemented before. The Virtual Point transformation allows engineers to couple measured FRFs with simulated FRFs & to make reliable full-vehicle models available earlier in the development process.

Adjust all possible measurement settings even after testing

- Design of experiment:

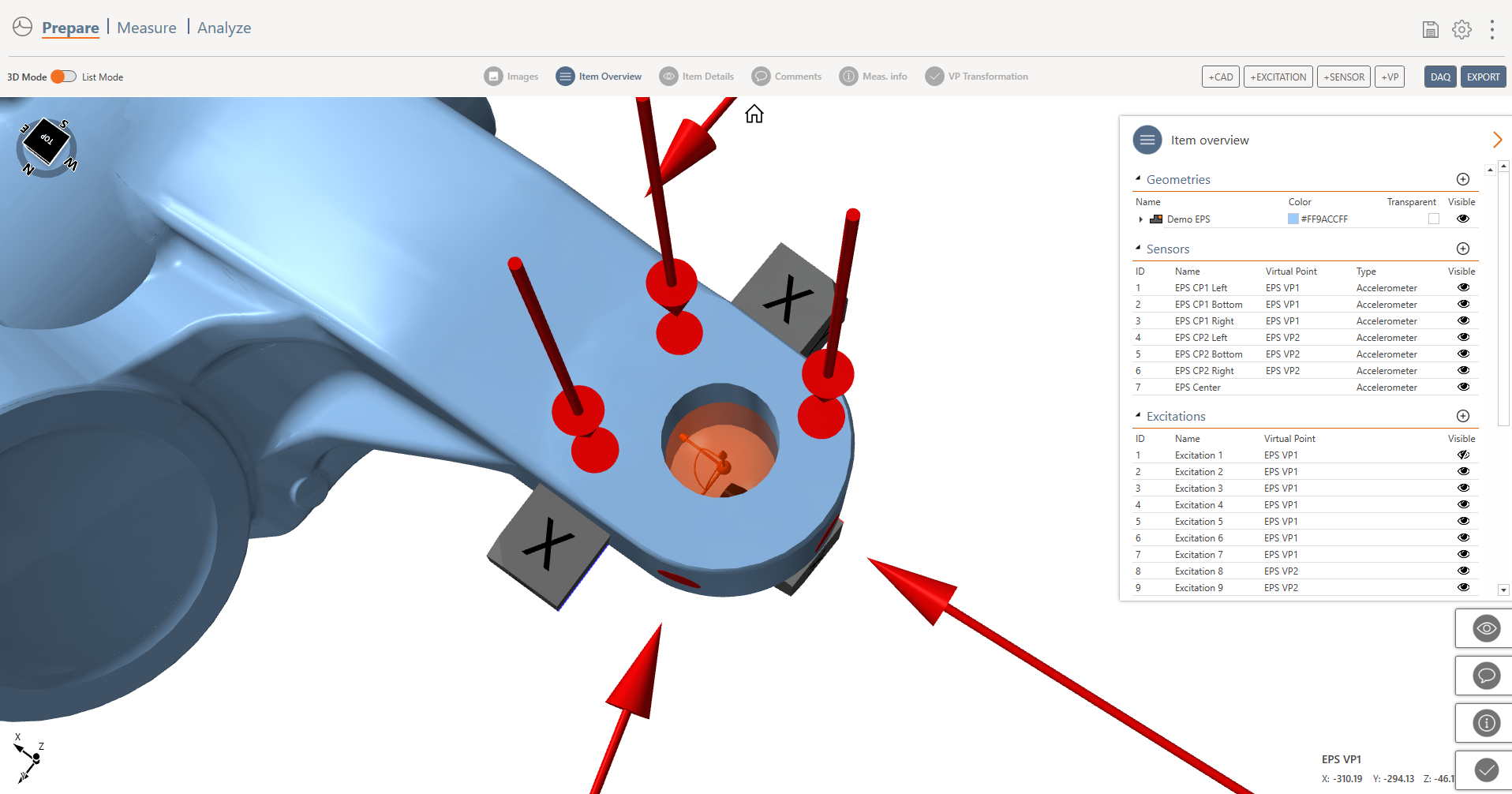

- Place sensors and impacts in the high-performance 3D environment, which gives immediate visual feedback and later allows for visualization of results.

- Define Virtual Points for compatibility with FE models

- Add photos to document and crosscheck your setup in DIRA

- Check the quality of your measurement setup for applying the Virtual Point Transformation

- Align all involved parties:

- DIRAC is used to define goals, design the experiment and inform measurement execution.

- Consistent way of describing measurements for an efficient modular R&D process

The measurement data quality is continuously controlled on multiple levels

- Measurement data import:

- Import of CAD geometry: Support for popular CAD formats

- All Data Acquisition Systems are working with DIRAC through ASAM-ODS (.atfx) import of FRF data, e.g. Siemens (LMS), Head Acoustics, Bruel & Kjaer or Müller-BBM systems (also LIVE available).

- TEDS Integration: Using the Müller-BBM MK2 system, DIRAC directly reads out all sensor information using TEDS. The advanced sensor database within DIRAC allows to quickly prepare measurements and update all information when connecting the Müller-BBM hardware.

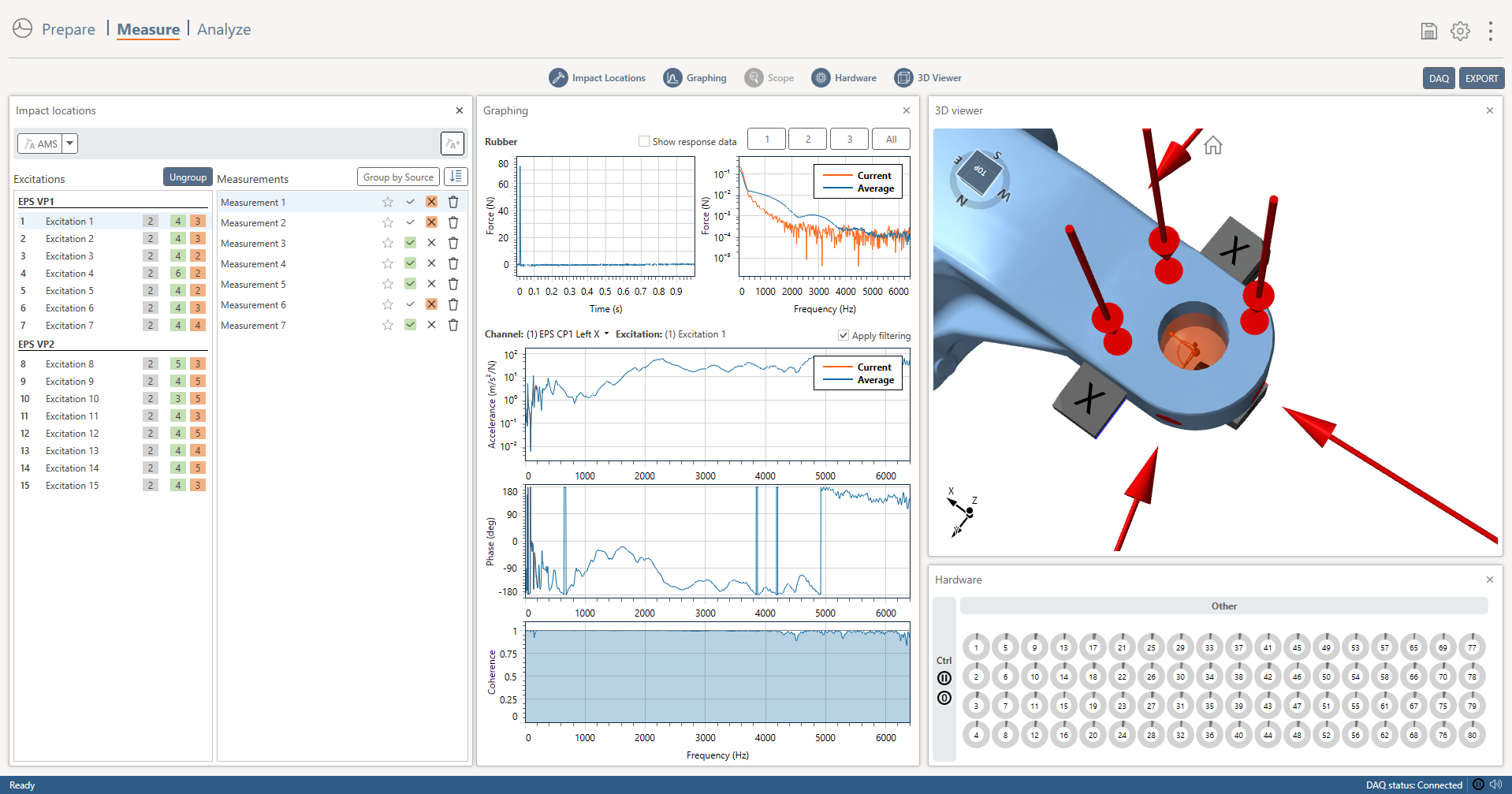

- Automatic Measurement Selection: Using this feature DIRAC automatically selects the most similar measurements according to your settings. This function also works live while you are measuring: it selects the best impacts while you are testing! (And of course, measurement errors are automatically excluded).

- Multi-Hammer Merge: Connect two (or more!) impact hammers simultaneously and merge the measured data directly! Different impact tips such as rubber or nylon excite different frequency bands.

- Measurement Transparency: Intuitive navigation through the measurement execution using the 3D environment.

Matrix overviews and quality indicators

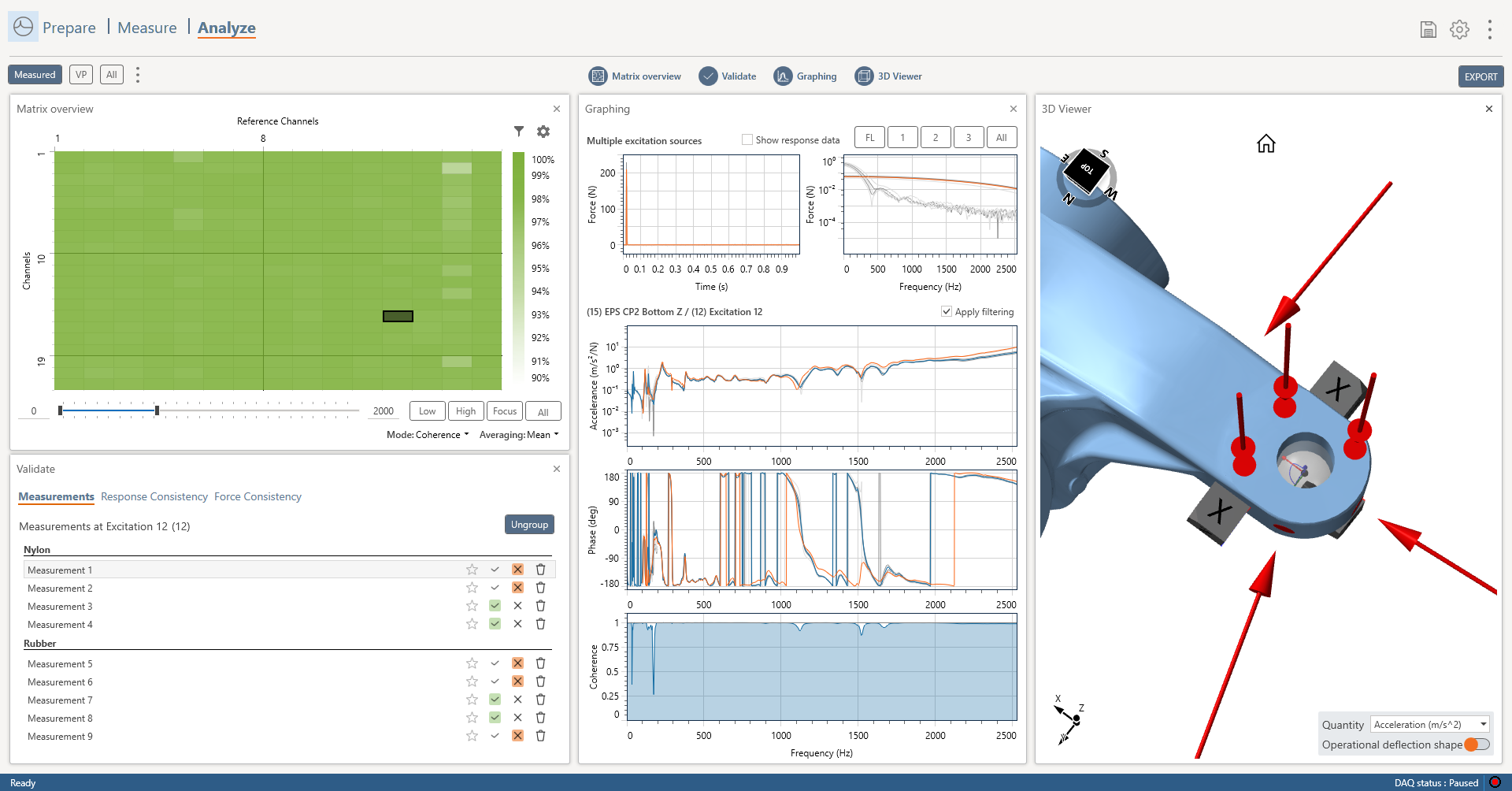

- Matrix Measurement Overviews: A measurement can involve over 10.000 individual FRFs. Our Matrix shows all data in a single overview. Incorrect measurements are directly spotted using several view-modes.

- Measurement Quality:

- DIRAC includes checks for outstanding model quality. From the Measurement Preparation with DoF contribution insights, Signal Checks, classical FRF checks (passivity, coherence), up to checks on the resulting model. This valuable feedback makes sure it is identified whether an interface is well described or if more measurements are required.

- Smart data and sensor checks ensure the measured data streams on the lowest level have no flaws, such as overloads, low signal-to-noise or double pulses.

- Consistent calculations ensure the measured data is in physical accordance with the known location and the orientation information as used in the Virtual Point Transformation. Wrongly mounted sensors, swapped cables and off-position impacts are detected this way.

- Operational Deflection Shape Visualization: Visually inspect the measurement results using the ODS-viewer. Export results (.gif) to share them in presentations.

- Virtual Point Transformation: 6-DoF Drive Point measurements are easily available using Virtual Points: your measured data is transformed for a perfect DrivePoint measurement.

- Post processing: Calculate Driving Point stiffnesses, bushing stiffnesses, symmetrize FRF data, or transpose your matrix of reciprocal measurements.

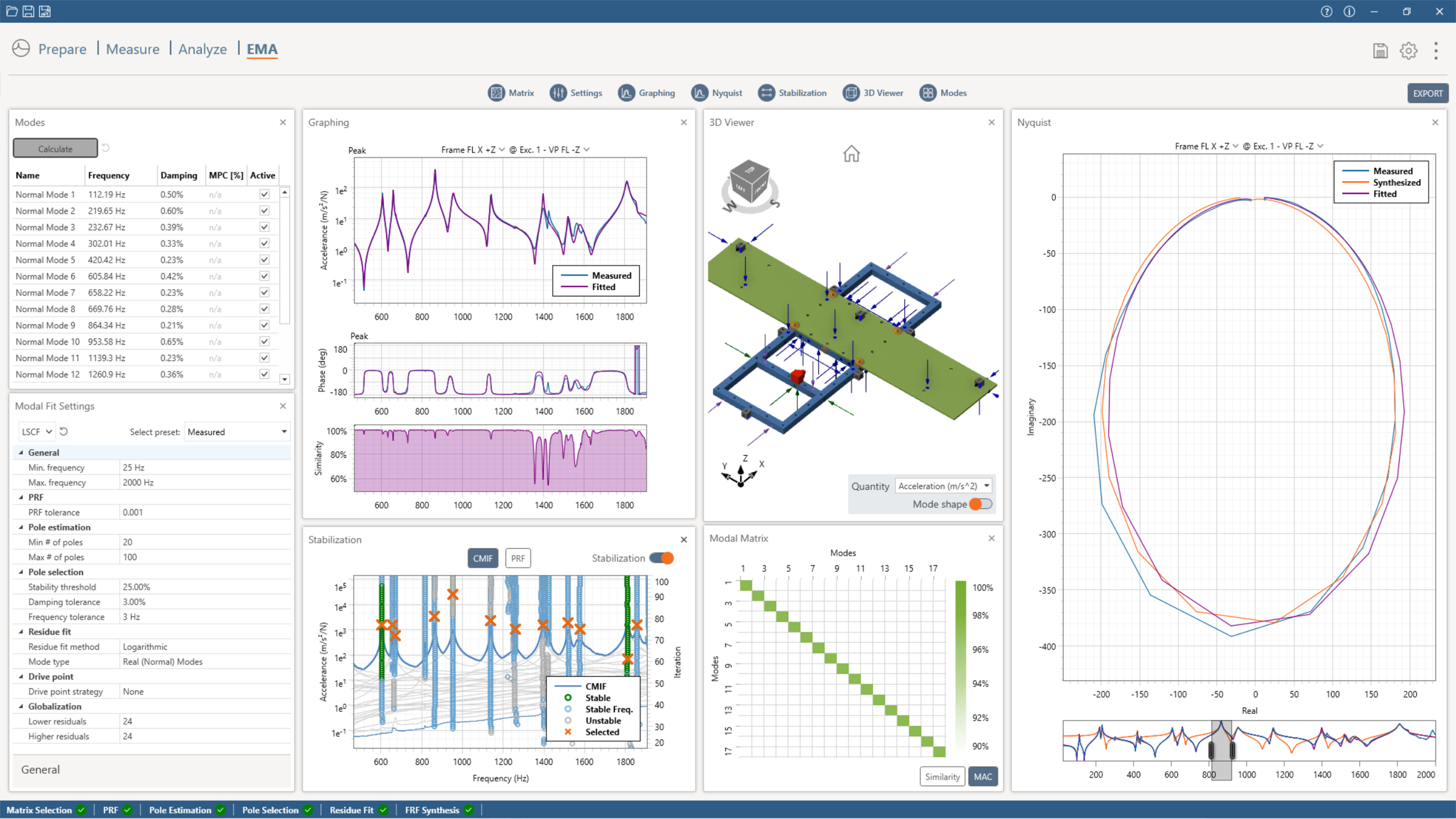

Perform Experimental Modal Analysis on test data and VP transformed data

The Experimental Modal Analysis (EMA) module allows you to perform a modal analysis study of your structure. The algorithm used by DIRAC is based on the Principal Response Function (PRF). The PRF helps to reduce the effect of noise and to fit modes on a large number of FRFs quickly.

- Possibility to select the modes of the synthesized FRFs.

- Visualization of original, fitted, synthesized FRFs, as well as normal and residue modes.

- Visualization of modes in the 3D viewer.

- Full flexibility on the modal fit settings.

- Stability diagram with poles and iteration information.

- MAC and similarity matrices.

- Nyquist diagram.

Ready to use in Simulation Packages or Dynamic Substructuring applications

- Time-saving integration for further analysis:

- SOURCE for Blocked Forces and TPA

- VIBES Toolbox for MATLAB for Dynamic Substructuring

- COUPLE to assemble, predict and optimize your NVH design in a complete modular workflow

- Export File formats:

- Measurement setup (XLSX)

- FRF results (ATFX, UFF)

- Mode shapes (GIF)

- All-containing export (MATLAB)

Our clients

“As an automotive engineer working on suspension level NVH performance development projects, I was stunned how the Virtual Point Transformation technique maximizes the accuracy of the systems’ FRF measurement result. I am absolutely confident that DIRAC’s CAD based user-friendly GUI also intuitively guides any engineer to get familiar with the software in no time. With the live quality indicators in DIRAC, you will get everything done right in the first trial. VIBES.technology has always been there for me throughout the whole project to support carrying out quality FRF measurements. Their quick and agile adaptation of customers’ opinions in updating their software is also one of the strong aspects the company offers.”

– David Song, Senior Research Engineer Hyundai Motor Company R&D division –

Combining DIRAC with SOURCE and COUPLE

DIRAC in combination with SOURCE is the most effective solution for Blocked Force calculation! Gather your FRF Data from your favorite DAQ systems using native ATFX import.

DIRAC + SOURCE ensures:

- Design of Experiment using the unique 3D preparation capabilities of DIRAC.

- Virtual Point Blocked Forces and Moments. This creates 6 degrees of freedom per coupling point, indispensable to capture all source characteristics.

- Transferability of Blocked Forces between test bench and vehicle, as the virtual points guarantee true compatibility at the connecting points.

- Higher bandwidth of validity, thanks to rotational FRFs and innovative test-based modeling features.

- More quality control in the Blocked Force calculation process.

Explore

More about DIRAC

Do you want to increase the quality and speed of your sound & vibration design process? Request a free demo or contact us about our orientational tech program to see how DIRAC can help you achieve this.