Virtual Point

Virtual Point Transformation

The basics

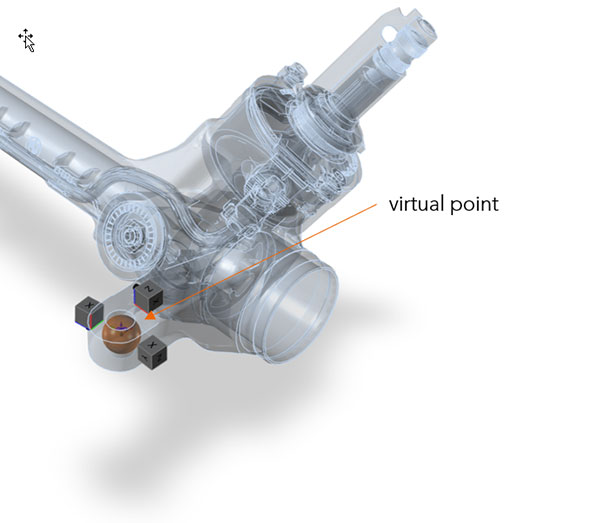

A virtual point (VP) is an interface used to connect components which allows the engineer to build up, for example, a full vehicle model. The point is “virtual” because typically it cannot be measured directly. By placing sensors around the VP and by assuming the local region behaves rigidly, DIRAC transforms the measured data as if it were measured at the VP.

The Virtual Point includes both translational and rotational degrees of freedom, data which traditionally is impossible to obtain. The transformation also gives valuable insights about the quality of the measured data and the resulting FRF model. Force impacts are transformed in a similar fashion.

See the short video below, explaining how virtual points are used in practice.

Why use Virtual Points?

A truly modular engineering approach requires exact and well defined interfaces between components. Using traditional (software) products, engineers are not able to perform measurements within the interface between two components. Our unique Virtual Point Transformation changes this:

- Measurement data is transformed as if it were measured at the exact interface location.

- It allows to measure FRFs in 6 degrees of freedom (DoF) including rotations, rather than only translations in 3-DoF.

- At higher frequencies, e.g. generated by electric drivelines, rotational degrees of freedom are crucial to include because they can have a high contribution in the overall transfer and resulting sound levels.

Accurate and reliable Virtual Point FRFs created with DIRAC are key to successful sound & vibration engineering and are crucial to perform advanced analyses such as Dynamic Substructuring or Blocked Force source characterization.

Unique software solution

DIRAC is unique on many fronts, yet truly outstanding are the intuitive way of guiding engineers during the measurement and the integration of the Virtual Point methodology. With the live quality indicators available in DIRAC, measurements will be done first-time-right, saving up to mutliple days on a single measurement campaign. The Virtual Point Transformation allows engineers to couple measured FRFs with simulated FRFs, making reliable full-vehicle models available earlier in the development process.

Workflow for Virtual Point Transformed FRFs in DIRAC

- Define the interface

Identify the coupling points of the component to its neighboring substructures. At each interface a Virtual Point can be defined: a 6-DoF ‘node’ that allows to couple the FRF model. - Prepare the measurement

Use the CAD-based measurement preparation to design the experiment. The Virtual Points are typically not accessible for measurement themselves; therefore acceleration sensors and (force) inputs are placed close to the Virtual Points. DIRAC will transform all the data as if it were measured at the Virtual Point. Sensor specifications are all set in the sensor database in DIRAC to make the actual measurement plug & play. - Perform the measurement

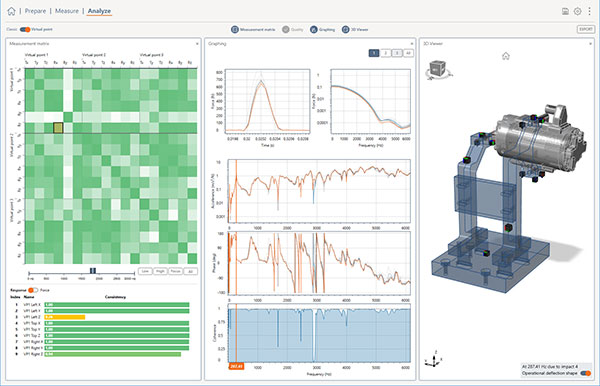

First, set up the hardware according to the prepared experiment. During the measurement DIRAC will share live feedback about the model quality, using the sensor specifications, the geometry of your experiment and smart background checks. The 3D viewer guides the process. - Analyze the data

Switch to the Analyze mode to see how the model is created from the measurement data. The operational deflection shape (ODS) is visualized, and the advanced browser allows to quickly view the measurement results as a whole or zoom in on a single FRF. - Export the VP FRF model

Use the FRF model in MATLAB, in ASAM-ODS viewers or in simulation packages as MSC Nastran and Ansys for further analysis! All data formats are open to ensure DIRAC fits into existing workflows.

Next steps - Modular way of working

Measuring the exact interface location (with VP) is required for a modular engineering approach. VIBES applies a modular approach towards sound & vibration design. This allows a clear separation of responsibilities and reduces the number of measurements required. We believe that a modular “component-based” way of working with open data standards allows engineers to work most efficiently on challenging topics. To further reduce costs, engineers can even combine measured and simulated component models, enabled by the Virtual Point method.