Prediction of NVH performance by combining test data and FE models

Using the blocked force approach an overseas OEM was able to predict the NVH performance by combining test data and FE models and reduce interior noise by ~15 dB. Our DIRAC software was used to prepare, measure and analyze the FRF measurements. While performing the actual measurement, every single measurement point was evaluated on the spot, using virtual point technology and quality indicators, therefore optimizing the process and duration.

The project

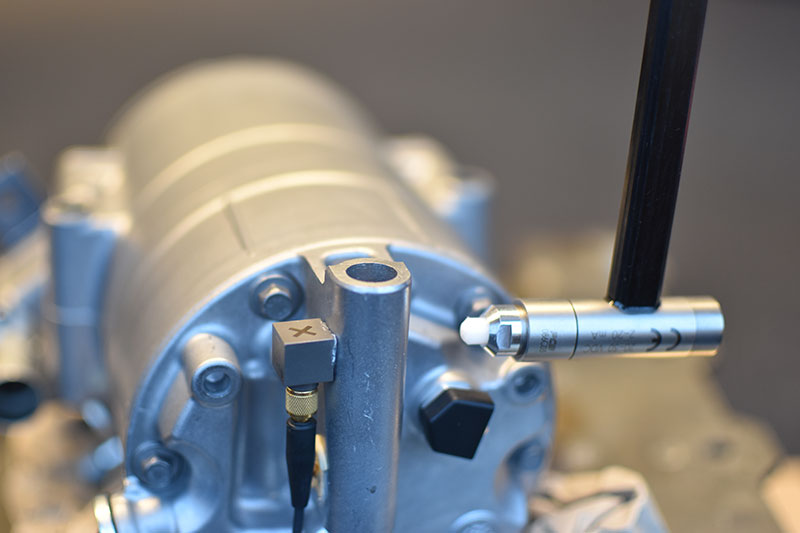

For an electric vehicle OEM, VIBES analyzed the NVH performance of an e-compressor. A prototype e-compressor was available, a physical prototype of the full vehicle was not. To still obtain results, the structural contribution of an e-compressor to the interior noise was simulated using blocked forces. The OEM had to decide on the packaging of an electric compressor.

Traditionally, compressors are mounted to the internal combustion engine which helps to minimize the transmission of structural vibrations. With electric vehicles such mounting is not feasible and new isolation stages must be designed to meet the desired NVH performance in the vehicle.

The goals

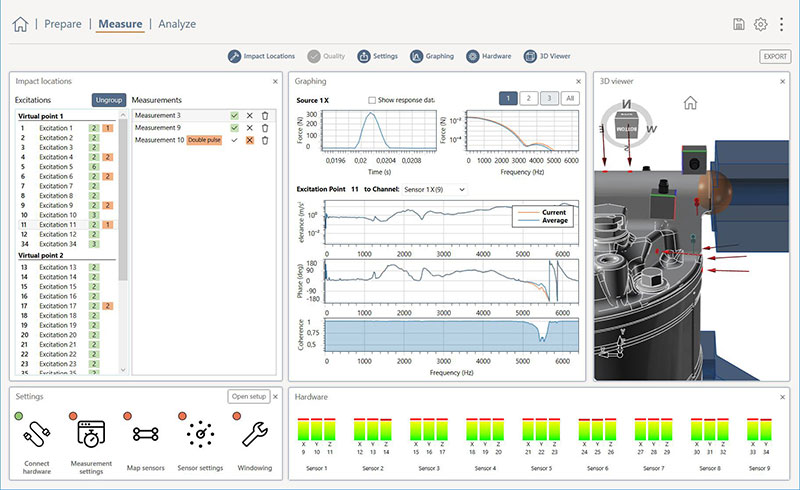

- Obtain an accurate source description with blocked forces on a test-rig, in the frequency range of 0 – 3 kHz.

- Obtain the blocked forces at a set of key operating points, such as various pressures and speeds.

- Obtain resulting force spectra compatible with Finite Element Models for further analysis and decision making – the virtual point transformation enables this compatibility naturally.

The approach

The execution of the project follows steps 1 to 5 of the Source Characterization Workflow as the in-vehicle noise predictions themselves were performed by the customer. The compressor testing environment was provided by our partner IPETRONIK. The design of the supporting structure for the compressor was performed and analyzed in-house, to ensure a correct dynamic performance of the test bench for the characterization.

We used DIRAC to prepare, measure and analyze the FRF measurements. While performing the actual measurement, every single measurement point was evaluated on the spot, using virtual point technology and quality indicators. This ensured that the resulting blocked forces of the compressor were independent from the testing environment.

The results

The key results in the project:

- Using the measured blocked forces, the OEM was able to predict the NVH performance of the compressor in the vehicle – through a hybrid simulation combining test data and FE models.

- Based on the simulations, the customer decided to add an additional isolation stage at the mounts, saving ~15 dB on interior noise.

- The project demonstrated the power of a fully modular NVH approach, with a supplier in Europe and the predictions performed overseas at the OEM engineering department.